Orbiting Rotor Compressor

Seeking cooperation

If you want to cooperate to make prototypes for your industry, please contact: info@flycarpet.net. We have rapid design software to adapt to your requirements quickly.

What is Star Scroll Compressor?

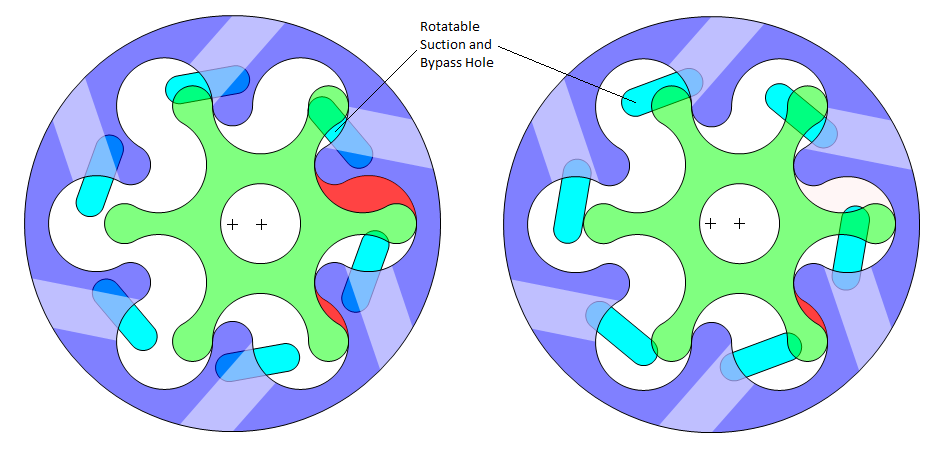

In a Star Scroll Compressor, a fixed outer part has multiple short scroll lobes extend inward, a orbiting part has same number of short scroll lobes extend outward and form multiple scroll pairs with the fixed outer part int a star pattern during orbiting.

The orbiting part is enclosed inside fixed part and two cover plates fixed to the fixed outer part, the two cover plates function as fluid suction and discharge controller respectively. A reed valve attached to the discharge plate to prevent the output fluid from returning.

Why Star Scroll Compressor?

1. Simple structure with least number of parts

No anti-rotation device: the multiple scroll pairs themself form a anti-rotation structure.

No axial suspension structure: no axial force applied to the orbiting part.

A novel radial compliance structure also works as counterweight.

2. High volume efficiency

Reliable omnidirectional sealing:

Axial side: both ends of compression chambers are sealed by two cover plates, which are simple flat surface.

Flank side: a novel radial compliance design can push the orbiting part against the fixed outer part to any desired direction to seal the compression chamber. The pushing force is proportional to the output pressure that also minimizes the harmful friction.

3. Quiet and smooth output

Very low vibration because of the circular orbiting path: the centrifugal force can be highly balanced by counterweight.

The multiple scroll pairs work succesively and fluid outputs are overlaped, the whole output flow has very low fluctuation.

4. Flow adjustable

Just simply rotate the suction plate.

5. Compact size/High speed(RPM)

It can run at high speed because of very low vibration.

The compression chambers are also designed larger to reduce the compressor size.

6. Long lifetime

Wear of contact surface won't increase the leakage because of the radial compliance design, instead it makes the scroll pairs run-in overtime and increase the sealing performance.

About Orbiting Rotor Compressor

Compressors consume 30%~40% electricity globally. Any Improvement for compressor is meaningful to our environment. We dedicate to make a new kind of compressor that is more efficient, low cost, quiet and flow adjustable.

This compressor is designed with an orbiting(or translating) rotor. Without reciprocal motion it runs fast and quiet and its size can be reduced remarkably.

Unlike the screw and scroll compressor which have constant compression ratio and not so efficient at variable real status, our compressor uses reed valves to ensure it always output the needed pressure.

Adjustable flow makes it possible to save energy at variable load.

Efficient sealing design makes it work efficiently.

The compression structure is self-engaged without extra anti-rotate parts, so it has smaller number of parts than scroll compressor.

Its simple and strong structure make it reliable and easy to be manufactured.

Novel Working Principle

As shown in picture and video, this new compressor works different as all other styles. During the rotor translating circularly, the rotor teeth and shell teeth are engaged and form closed spaces which volume change is used to apply pressure to the gas inside.

With bypass slot for each compression chamber, the flow regulating plate can change the flow rate by simply rotating operation.

Update 1: First Miniature Air Compressor Prototype Works Well

To reduce the cost, the first prototype was designed as a small air compressor.

Our next step is to build a regular size one for detailed performances and lifetime test.

Working Principle

Latest Prototype Test

Applications

All the applications with compressors, vacuum pumps etc. Such as air/natural gas processing and pressurizing, refrigeration and air conditioning, plant product line etc. Applications have covered most industries in the world.

Oil free air compressor, for medical application

Market

There are over 100 million compressors produced every year in the world.

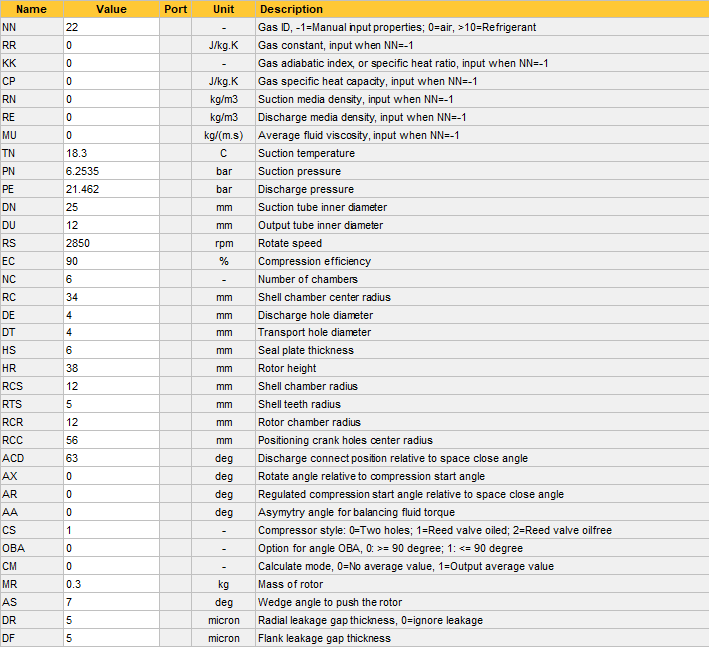

Calculation Model

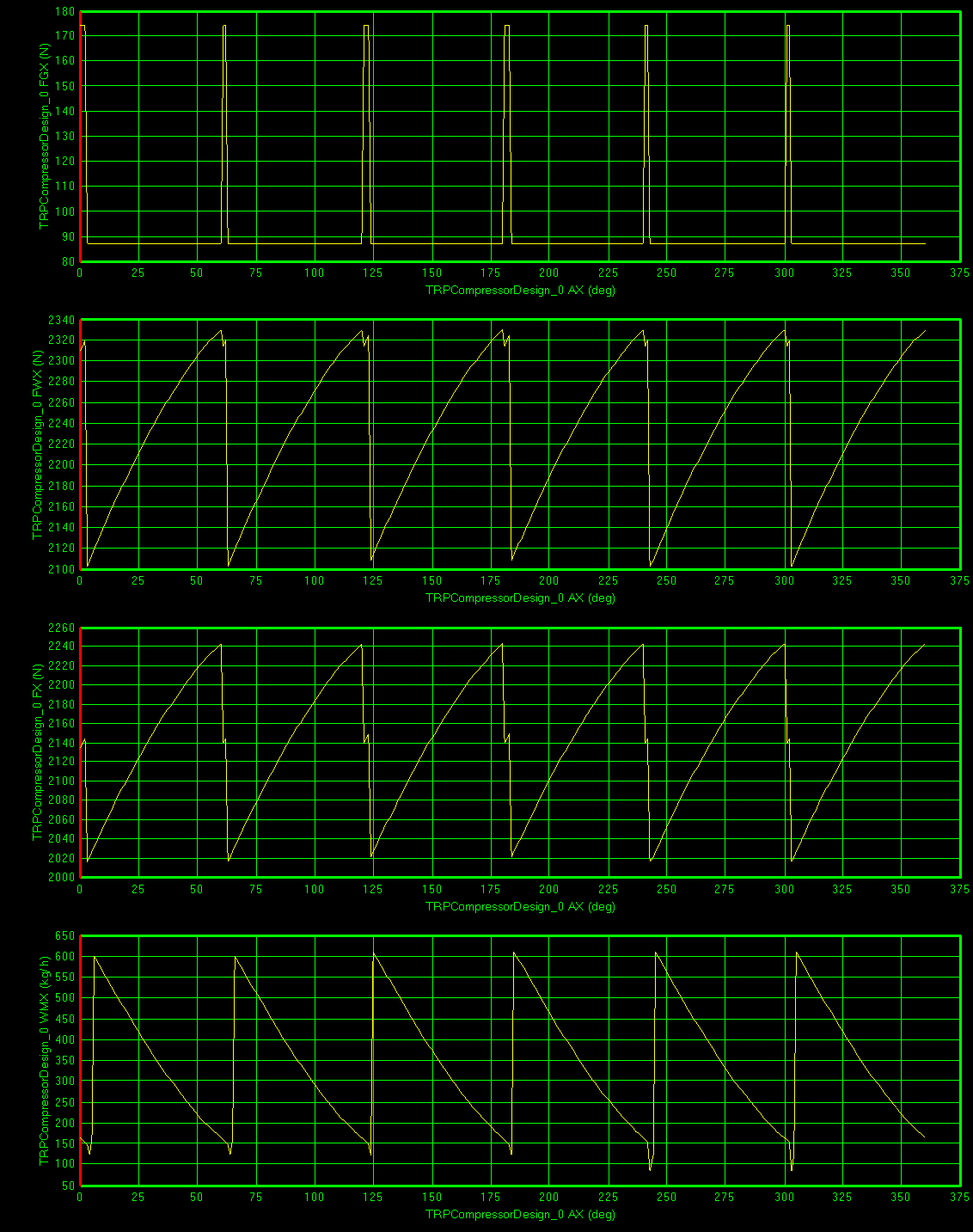

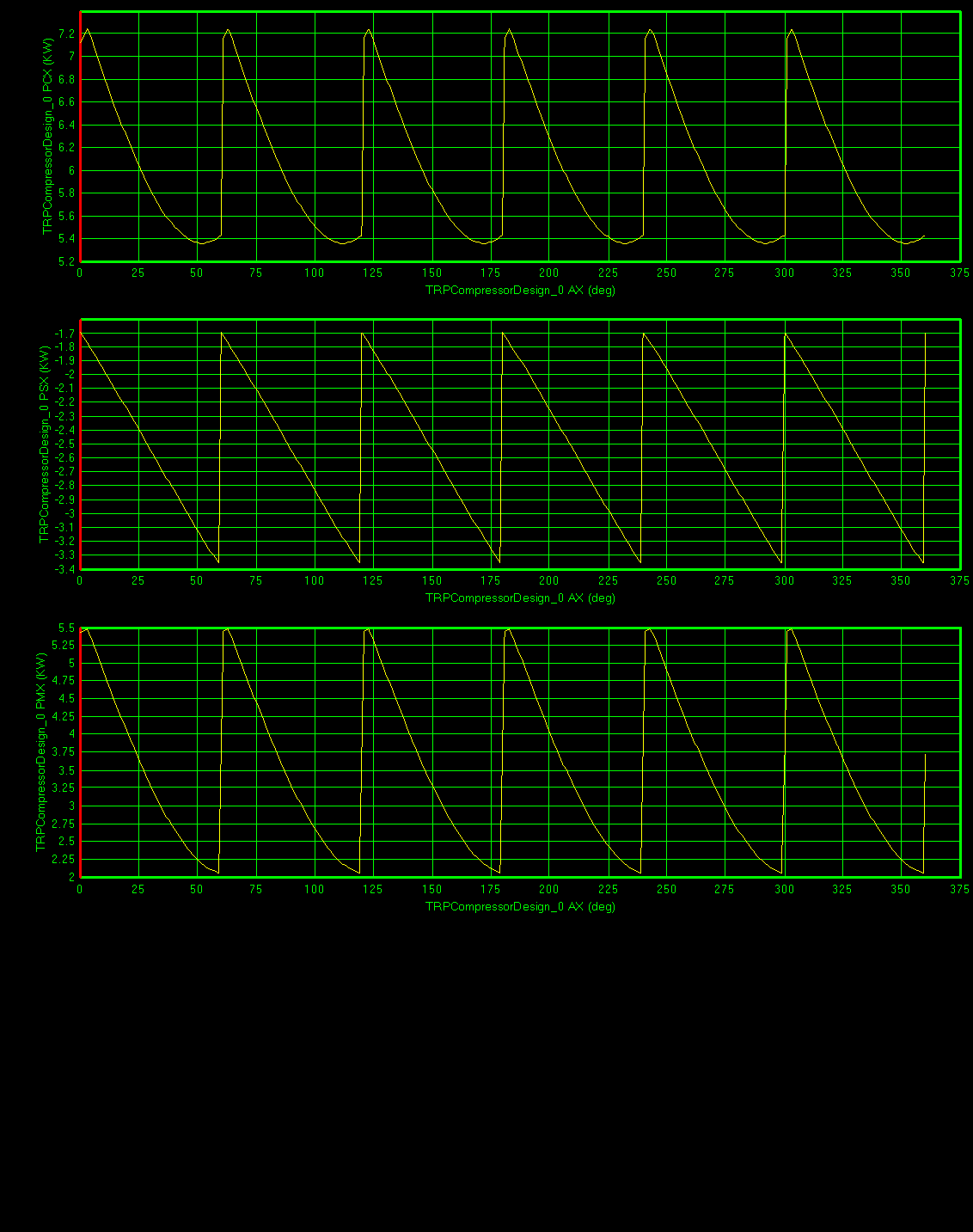

This model calculates a refrigerant R22 compression process, ARI standard conditions, 14 cum/h, 2850 RPM, 6 chambers, delivery volume 81.9 cc per rotation.

The model inputs and outputs are listed below.

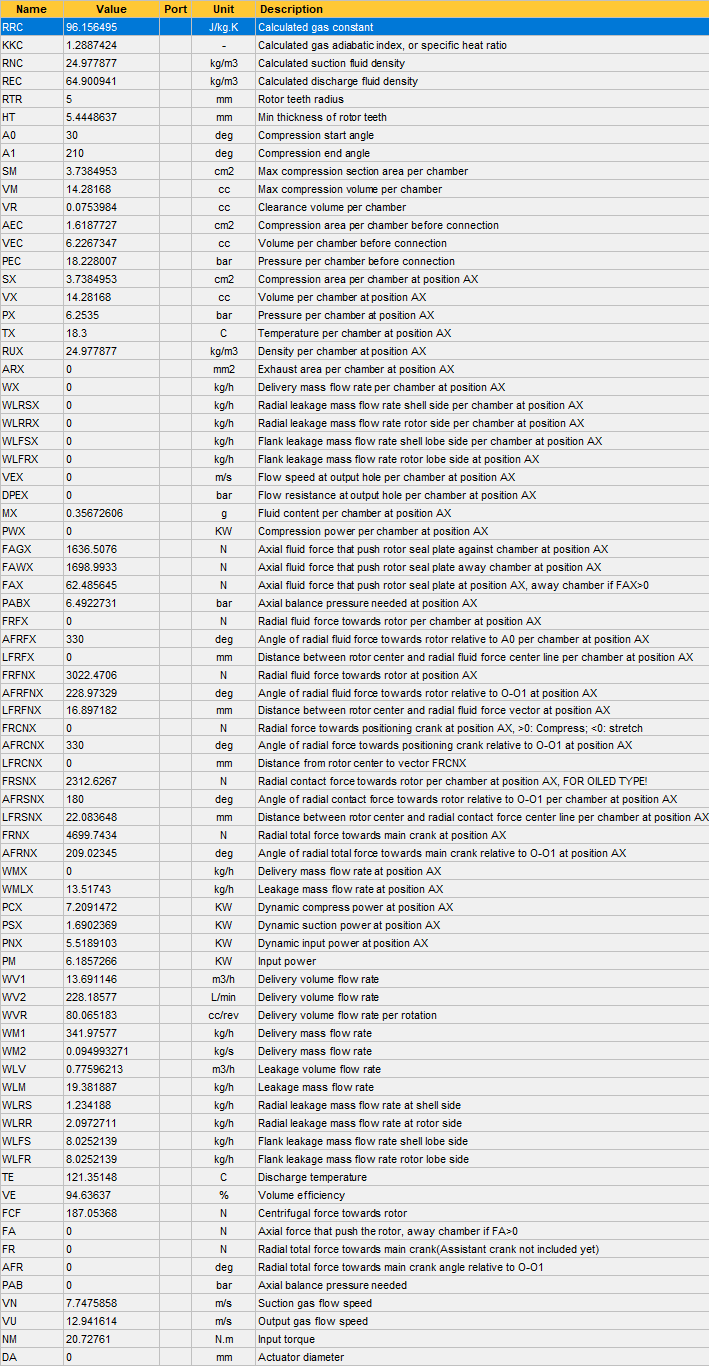

Calculated performance 1:

X --> Rotate angle position

Y --> Volume at per chamber, cc

Y --> Pressure at per chamber, bar

Y --> Mass flow at per chamber, kg/h

Y --> Power at per chamber, kW

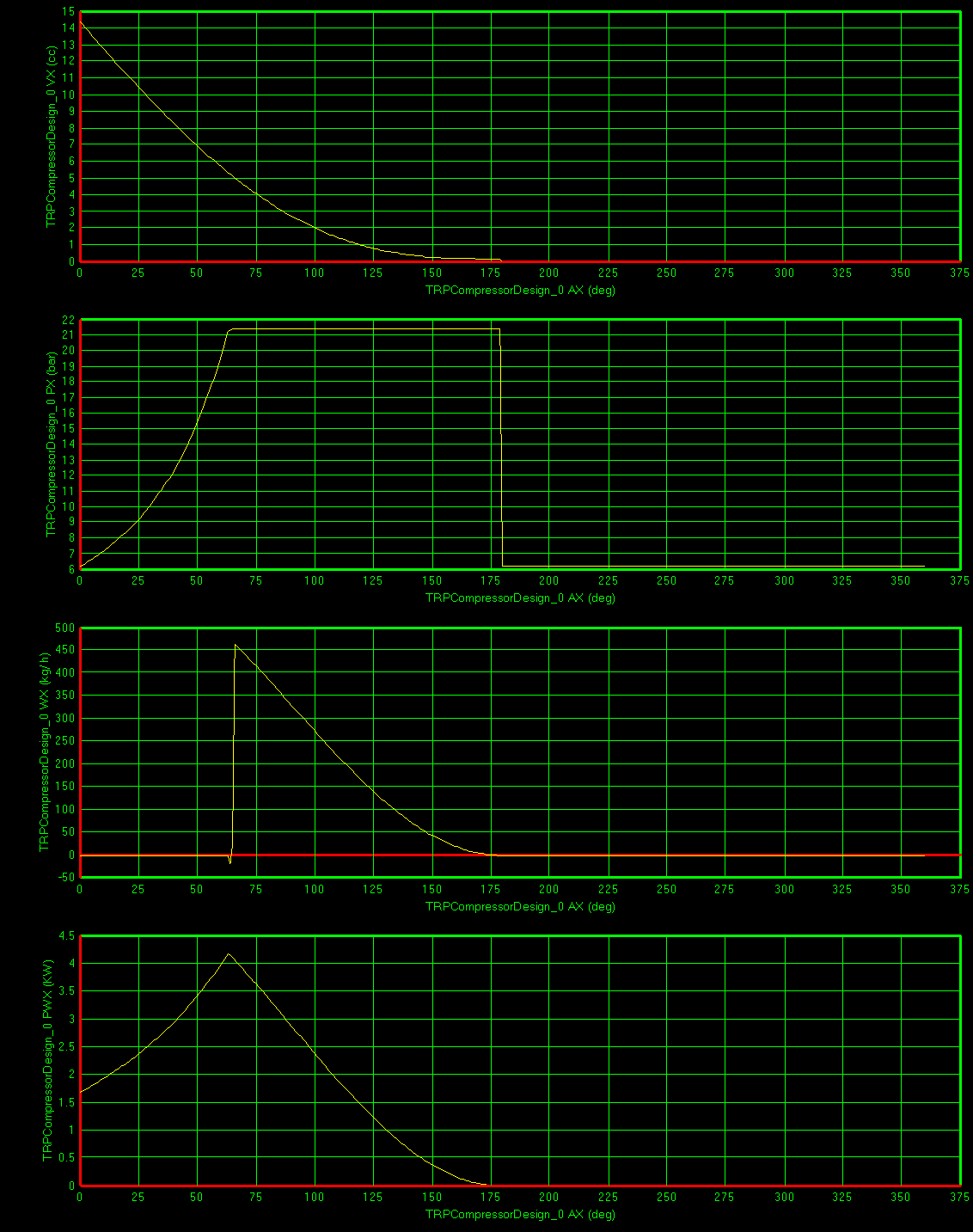

Calculated performance 2:

X --> Rotate angle position

Y --> Push force from discharge to rotor, N

Y --> Push force from chamger to rotor, N

Y --> Total push force to rotor, N

Y --> Total mass flow, kg/h

Calculated performance 3:

X --> Rotate angle position

Y --> Compression and discharge power at the position, kW

Y --> Suction power at the position, kW

Y --> Total power at the position, kW

Psychrometric Chart + Duct Calculator

Download V4.41 for Free Trial

Free Online Psychrometric Chart